So, how does the fruit become juice? Small scale fruit juice processing equipment might turn your garden yield to profitable business. As you will see, fruit juice extraction is not only using press! It involves more steps, because the juice should not only taste good.

It should also be visually appealing and be available all year round. You can leave the process to the fruit juice manufacturers or take care of the fruit juice processing yourself. You can produce high-quality fruit juices with modern technology and preserve the fruits’ valuable ingredients and taste as best as possible.

Juice production always occurs in almost the same steps:

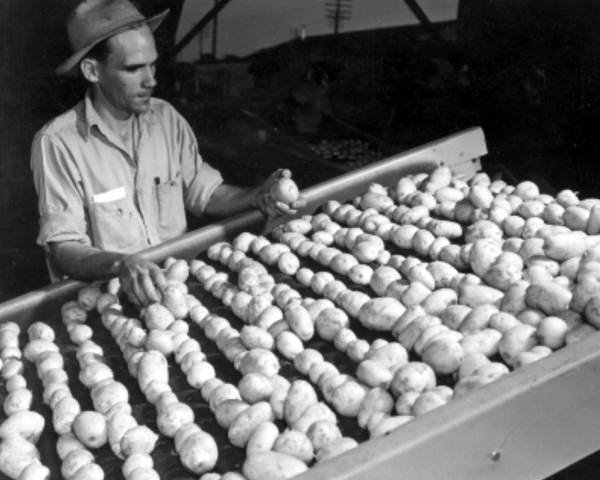

- delivery of raw material

- washing/sorting

- pressing

- filtering

- pasteurization

- bottling

- packaging

The individual production steps are tailored to the type of fruit to be processed because, for example, apples have different processing requirements than grapes or oranges.

Small Scale Fruit Juice Processing Equipment

What type of equipment do you need for small scale fruit juice processing?

- Washing machine

- Sorting machine (optional)

- Shredder

- Belt press/decanter

- Separator (optional)

- Pasteurizer (or simple heating, as a cheaper option)

- Filler (bag-in-box, gravity, other)

List of juice you can manufacture

You can produce fruit juice from many sorts of fruit and even vegetables, such as:

- Apple and pears

- Berries (raspberries, currants, etc.)

- Cherries

- Elderberries

- Sea buckthorn

- Dates

- Grapes

- Citrus fruits (juice and essential oil)

- Tropical fruits (mango, pineapple, etc.)

- Carrot

- Tomato

- …and many more.

Depending on the type of fruit, there are significant differences in the juice yield. It can be 65 to 80 percent for apples, pears, and rhubarb. In the case of currants, it is even almost 80 percent. It is much lower for citrus fruits, at around 50 percent.

The pressed fruit, the so-called mash, which contains the peel, seeds, and remains of the fruit pulp, is often used for other products.

Separation technology plays a crucial role in juicing and helps preserve the valuable components of fruit and vegetables.

Which separating unit is used depends on the type of fruit or vegetable to be processed. Parameters such as the particle size of the turbid matter to be separated and the solids concentration in the mash are also decisive (decanter, belt press, separator). Another decisive influencing factor is the ripeness of the raw material.

Decanters extract the juice from finely macerated fruit and vegetable mashes. They are characterized by a high juice yield and flexible application options.

The belt press is used for dewatering products with high solids content, e.g., when juicing fruit mash. The machine is characterized by high juice yields and a high level of dry matter in the pomace.

Self-cleaning disc separators are used in the “clarifier” version, e.g., to separate undesirable fines in the end product. Due to the high centrifugal forces, you can remove even the finest suspended particles.

So, as you see, different technological solutions will be required depending on your raw material and the final product you intend to produce. You need to do some market research first and decide whether it is the production of natural juice, raw juice (non-pasteurized), or the production of concentrates.

Apple Juice Production Process

The prime example of raw material utilization is the apple. It is 100 percent processed. The juice yield is around 75 percent. Twenty-five percent is pressed mash with skins, seeds, and remaining pulp, called pomace. The pomace is mainly used for the production of apple pectin. In addition, it is used as animal feed and flows into energy production.

This makes using apples to produce apple juice a prime example of a modern circular economy. Be aware that recycling residues during production might also be subject to legal requirements in some jurisdictions.

How does the standard apple juice processing plant work?

Actually, it undergoes the same fruit juice processing steps as with the other fruit. It also can be undertaken using the same small scale fruit juice processing equipment. The apples are delivered from the surrounding area using the contract with local suppliers, which means the supplier gets ready-filled juice for his apples. The apples are collected in silos and processed fresh on the same day.

The apples are pre-washed via the water flume and transported to the mill, where they are crushed into a mash. Before they are shredded, they are sorted out and washed a second time with fresh water.

The mash is further processed on the press. Approx. 20 gallon of juice are produced from 220 pounds of apples. The rest, the so-called pomace, is picked up by hunters to feed the wild or sold to the pectin factories. The apple is therefore fully utilized.

Immediately after juicing, the apple juice must be preserved. For this purpose, it is gently pasteurized using a plate heater. Or you can gently evaporate juice under a vacuum if you want to produce concentrate. The juices and concentrates are stored cool and dark in sterile tanks until bottling.

Another cheaper option of processing doesn’t include pasteurization. The apple juice is gently heated and filled on automatic filling lines into the bottles, tetra packs, or bags. The heating is used for preservation here.

If you fill into bottles, the bottles are washed before doing that. Broken bottles are sorted out. After filling, the bottles are sealed, labeled, and packed in crates.

Crushers and Shredders For Fruit Juice Processing

You absolutely need an excellent fruit mill or shredder to prepare fruit for a fruit press. It is so because the chopped fruit’s consistency is decisive for the pressing result and the amount of juice obtained from your valuable fruit.

Basically, the fruit mills differ in the grinding technology used. Here you can choose from pome fruit grinders with cutting knives, shredders, or centrifugal mills (which gently rub the fruit through suitable perforated grids) or classic, manual hook roller crushers for fruit or pure crushers for berries.

In addition, there are different types of fruit mills in various designs, such as fruit mills in stainless steel, with plastic parts, etc.

Of course, before buying one, please ensure that your chosen fruit grinder complies with all food safety standards and bears appropriate markings. A fruit blender or mash mill usually requires hardly any maintenance. With careful cleaning, most of the maintenance is already done! You should only sharpen the cutting blades of the machine from time to time.

Electric Hydraulic Fruit Press

Fruit juice processing equipment might be expensive. Don’t want to invest in a fully-fledged belt press? Electro-hydraulic fruit and berry presses with a wood basket and trolley might be an option for your consideration.

Mobile electro-hydraulic fruit and berry presses are known for their durable design. You just need to press the basket for easy filing on a pull-out press tray, which is sometimes equipped with a trolley. Push the button, and the electrical control of the press hydraulics enables a quick and easy pressing process.

The cut-off pressure of the hydraulic motor can be set individually on the pressure gauge of the press in more advanced models. The press switches off automatically if the switch-off pressure is reached during the pressing process.

The electric hydraulic fruit press is automatically reloaded if the pressure drops below the working pressure due to the lack of raw material. The pressing force may reach 350 bar or more, depending on the model.

Durable, close-meshed press bags prevent the mash from escaping through the press basket, even with finely ground fruit. This significantly reduces the proportion of sediment in the final product.

We recommend dividing the pomace using press cloths and grids for optimum juice yield and a quick pressing process. The more clothes and grates used, the greater the amount of juice. The optimal height of the mash layer is 20 cm.

Example technical specifications:

- Basket size: 24 x 30 inch

- Basket with trolley

- Interchangeable basket and interchangeable trolley

- Basket capacity: 55 gal

- Press pressure: 6000 pounds

- Working pressure: 350 bar

- Motor power: 1.0 kW

- Voltage: 380 volts

- Pressing time: approx. 40 minutes

- Size: 50*60*90 inch

- Weight: 390 kg

How Do You Pasteurize Juice

Pasteurizing the juice: what does it mean?

Pasteurization is the brief heating of certain foods to 176-194°F to kill microorganisms. Pasteurization is a process invented by Louis Pasteur, who also gave the technique its name. In the 19th century, he recognized that most microorganisms are killed off by brief heating, and the food can be kept longer – without any significant change in the product properties. After being pasteurized, a product is quickly cooled in order to avoid the development of other bacteria.

Today, in many countries, it is a legal requirement that certain foods be pasteurized. Certain foods, such as fruit juice, are pasteurized because they would spoil too quickly due to the natural presence of microorganisms. Pasteurization, therefore, significantly extends the shelf life of food.

How does juice pasteurization work?

Whether a juice is pasteurized cannot be seen just by looking at it. Due to the gentle heating, there is no change in color, and the consistency does not change either. Pasteurizing the juice only physically ensures that the fruit juice has a longer shelf life.

Fruit Juice Pasteurizer

Pasteurizer also belongs to small scale fruit juice processing equipment. As mentioned before, the pressed juice should be gently pasteurized in juice production. You should use a special pasteurization process in which the liquid is heated to temperatures of around 176-194°F. This process now stops the fermentation of the juice. Product heating is a simple but powerful strategy to prevent your juice from spoilage.

All natural microorganisms that would cause the fermentation process are killed. This way, your product may be stored and used for extended periods.

How does pasteurizer work?

Using a plate heat exchanger reliably and safely pasteurizes your product. Highly viscous pulp and fiber products are heated with plate heat exchangers adapted in tube form, with single-tube or multi-tube systems used depending on efficiency and flexibility requirements.

After flash pasteurization, your microbiologically excellent products are cooled and transferred to the filler. This process can be continuous if a buffer tank is installed between the heater and the filler. Electronic temperature control ensures constant and gentle pasteurization of your product.

What does gently pasteurized mean?

Gently pasteurizing food means only heating it for as long as necessary. Because the longer food is heated, the greater the risk that the vitamins it contains will also be destroyed.

Cheaper Option – Bath Pasteurizer

A bath pasteurizer might be an option to go if you don’t want to invest a lot into a sophisticated heat exchanger pasteurizer. As the name suggests, bath pasteurizer contains a bath with hot water. Just put your already bottled product into this bath and set the right processing parameters. You can set a required heating temperature and maintain it at a constant level.

What is the difference between pasteurization and sterilization?

Pasteurizing food means briefly heating it to a temperature below 212° Fahrenheit. This kills many germs and stops enzymes. However, heat-sensitive microorganisms persist. That is the reason why juice, for example, does not keep indefinitely, even if it has been pasteurized.

On the other hand, sterilization means that the food is heated to around 266° Fahrenheit for up to an hour. The product is then completely germ-free. This results in a very long storage term – you can keep the sterilized product for several years on the shelf. However, this advantage doesn’t come without the cost – vitamins and good microorganisms are also destroyed in the process.

Manual Bag in Box Filler – Last But Not Least Among Small Scale Fruit Juice Processing Equipment

There is a wide variety of bag-in-box fillers on the market. Let’s have a quick look at a straightforward example here.

The bag-in-box filler can be a manual machine for filling 0.8-gallon, 1.3-gallon, and 2.6-gallon bags. This machine is especially suitable for hot filling up to approx. 176°F and is equipped with a calibratable weighing system. It is a tabletop model that can quickly be integrated into a small plant using stainless steel rack.

By installing a level switch (as an additional accessory) in the storage tank, the juice pump of the pasteurizer is switched off before it overflows. The installation of a thermometer is also recommended for hot filling.

How does it work?

- Insert bag

- Open the bag closure

- Fill the bag by reading off the calibrated scale

- Seal the bag

- That’s it!

Technical specifications:

- Length 25 inches, width 25 inches, height 40 inches

- Connected load 0.3 kW

- Electrical connection 230V/50Hz

- Weight approx. 90 pounds

- Tank volume approx. 13 gallons

- Made of stainless steel