A distiller for essential oils allows you to extract essential oils from herbs (fresh or dried) by treating them with steam.

Boiling water steams through the plant mass in the extractor and forces it to release essential oils. After the condensate cools, the oil in the flask remains on the surface of the water because its density is lower.

The easy-to-use still is suitable for hobbyists and laboratories for testing and small production work.

Really simple and cheap way to produce high-added-value aromatherapy products, essences, and aromatic oils.

Essential Oil Distillation Kit

Usually, even the most simple distiller for essential oils available on the market is equipped with a double aluminum bottom and a flat bottom. Explicitly designed for extracting essential oils from herbs using the principle of steam extraction and the recovery of aromatic water to obtain the maximum amount of essential oils.

Our favorite model is made entirely of AISI 304 stainless steel, with a dual-chamber Pyrex glass collecting burette for the distillate cooling circuit.

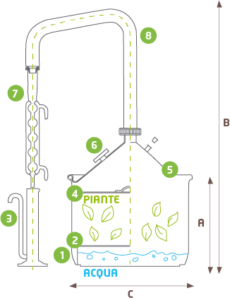

Schematic:

1 – boiler

2 – lower grid

3 – graduated cylinder

4 – upper grid

5 – cover

6 – thermometer

7 – capacitor

8 – collector

If required, you can also find larger oil and essence extractors from 3 gal (12 liters) to 66 gal (250 liters) or even bigger.

What Is The Best Way To Distill Essential Oils? 5 Simple Steps

Step 1. Prepare the raw material

Plants in the Lamiaceae family, such as peppermint, lavender, oregano, thyme, etc., are usually relatively easy to distill. Species belonging to this plant family are harvested immediately after flowering or just before it.

Experiment with harvest times, research, and observe the results to gradually build up the experience you need for successful distillation.

For other plants, especially those with thick leaves, and also when distilling conifers, it is advisable to cut them into 2-3 cm long pieces before distillation. Suppose the results of the distillation need to be more satisfactory.

In that case, it is possible to macerate before the distillation, i.e., soak the raw material in water or a special solvent for up to 48 hours. This will help soften the raw material and allow for better distillation results.

Step 2. Fill the still properly

Just starting to use the distiller for essential oils, you may have questions about how much raw material should be put into the device, how strongly it should be compressed, etc. Correctly filling the still takes some practice and monitoring the results.

The distiller for essential oils is filled by gently pressing the raw material down and laying an additional layer of raw material on top until the entire working volume of the distillation apparatus is filled.

It is essential not to compress the plants too hard, as there must be small gaps, cavities, and cracks for steam to pass through. On the other hand, if you do not achieve the required degree of compression of the raw material, you will produce less of the final product, and the hydrosol water may be weaker and less aromatic than it should be.

In any case, it is necessary to follow the instructions for the safety and operation of the specific device. More advanced machines are equipped with safety valves, which, if necessary, quickly reduce the pressure inside the device. Meanwhile, when the device is filled correctly, no excess pressure builds up inside the still.

Step 3. Distillation process – maintaining the right temperature, duration

After the still is appropriately filled, close it tightly and start heating. Choosing the right distillation temperature is a significant factor for both the distillation process’s efficiency and the final product’s quality.

As a general rule, always start with medium heat and reduce it if necessary. How do you know when the temperature is too high and needs to be reduced? First, it is required to monitor the flow of the product leaving the still.

The stream should flow in small splashes and drops. If it flows in a strong, steady stream, the heat is too high and should be reduced. Distillation times will vary from device to device, averaging 2-5 hours, depending on the plant material and the type and size of the still used.

Temperature

Temperature affects the rate of distillation. The higher the temperature, the faster the water is heated, and the extraction processes are accelerated while also destroying specific sensitive aromatic molecules.

Therefore, it is advisable to distill at a lower temperature and pressure in the still. This slow and gentle distillation takes longer but can preserve more aroma molecules by preventing them from breaking down too quickly in high heat.

It is beneficial to purchase a distiller with a built-in thermometer. This will allow much more precise control of the process temperature. The distillate starts to separate when the temperature reaches about 100 degrees.

It should be noted that atmospheric pressure can slightly affect the water’s boiling point, vaporization temperature, and, thus, distillation temperature.

It can be reiterated that the distillation should be slow and long. This is one of the criteria that has a significant impact on the quality of the final product. To collect the entire collection of volatile aromatic molecules, it is necessary to distill slowly, i.e., without overheating.

Step 4. End of distillation

The duration of the distillation process depends on the type of raw material to be distilled and the maximum possible yield of the product. As a rough rule, one kilogram of plant material should yield one liter of hydrosol water (note: not essential oil!).

However, these are just guidelines. Every distillation is different, even with the same plant. The distiller decides when to stop the distillation based on careful observation and experience.

It takes practice. If the distillation is stopped too early, the aroma will suffer because the heavier molecules, the so-called bottom notes, will not be collected.

If the distillation is stopped too late, the hydrolat will be too diluted, and its aroma will suffer as a result. True, since the essential oil is immiscible with water, there is no danger of the essential oil being too diluted by distillation for too long.

Step 5. Collection and bottling of essential oils and hydrolat

The hydrosol water drips from the condenser and must be collected in clean glass containers designed for that purpose. These vessels must be used only for distillation purposes to avoid extraneous odors.

If you collect several containers of hydrolat during one distillation, remember that they need to be remixed before bottling so that the final product has all, i.e., top, middle, and bottom notes of the aroma.

The smell of hydrosol water usually does not appear immediately after distillation. It may take several days or even weeks. Therefore, after distillation, the product should be allowed to “rest” for a week, and in some cases, it is recommended even up to a month. The smell finally stabilizes after about three weeks.

Hydrolats should be bottled in sealed, dark glass bottles and stored away from sunlight in a cool, dark place, ideally at a temperature of 14-17 degrees. If this is not possible, natural hydrosol water can be stored in the refrigerator. However, to avoid mixing the aroma with food smells, it is advisable to purchase a separate refrigerator for storing hydrolats only.

What Are Essential Oils, And Why Is Rose Essence Expensive?

As mentioned before, essential oils are concentrated oils found in leaves and flowers that give plants their specific scent.

They are volatile and evaporate quickly in the air. Also, essential oils break down much faster when exposed to bright, direct light. That is why they must be bottled and stored in dark glass bottles with tight caps.

As already mentioned, essential oils are separated from the plant material by steam distillation in a still. Two products are obtained during the steam distillation of plant raw materials: essential oil and hydrosol water.

Different plants produce different amounts of essential oil from the same amount of plant material, which is reflected in the essential oil price.

Interestingly, one of the most expensive essential oils is rose essence. Its price is so high because it takes about 60,000 rose flowers to produce about 1 oz (30 grams) of rose oil.

The flowers are picked by hand, usually, on the morning of the day, they will be processed. This is followed by an intensive distillation or solvent extraction process in a percolator.

Cheaper essential oils, such as peppermint essential oil, require less plant material to produce the final product during distillation. Considering that the distillation yield of peppermint essential oil reaches a maximum of 0.80%, approximately 4 lbs of peppermint leaves will give you about 0.5-0.7 oz (16-20 grams) of peppermint essential oil.

The remaining distillation product will be peppermint hydrosol water, which you can use as an air freshener, insect repellent, or aromatherapy.

So, the distiller will help you extract essential oils at home, using plants from your garden as raw material. However, it should be noted again that you will get quite a small amount of essential oil compared to the amount of hydrosol after a single distillation.

It has been mentioned that some plants, such as roses, need a huge amount of plant material to obtain a minimal amount of essential oil, so a distiller with a significantly larger volume will help you to process such a large amount of raw material.

However, you can certainly experiment and understand the intricacies of distillation and make essential oils and hydrosol water for your needs with the smallest stills or even copper stills.

So Why Should You Try Distilling Your Essential Oils?

- Because a distiller is a device that is really easy to learn to use.

- Because this is an exciting and valuable skill that will give you natural, home-made products.

- Because the house will smell great because, during the distillation of essential oils at home, part of the essential product also enters the room.

- Because mint grown in the garden can be used not only for making mint tea!

- Because hydrosol water can be used as a natural air freshener.

Conclusion

A distiller is a simple device with which, with a bit of skill, you can produce high-quality and natural products – essential oils and hydrosol water, also known as flower water. All this is from plants that you can easily grow in your garden or at home on the windowsill.

Hydrosols are a by-product of essential oil production. Essential oils are distilled from plant material using a distillation apparatus. The essential oils collect on the surface of the distillation flask and are separated from the hydrosol water.